麻豆AV免费在线观看钢管 / 保温钢管 / 久久亚91无码精品色午夜麻豆 / 螺旋钢管 / 直缝钢管 / 无缝钢管 / 镀锌钢管 / 管件 /

为客户提供更化、个性化的服务

IPN8710高分子无毒涂料麻豆AV免费在线观看钢管产品介绍: 一、组...

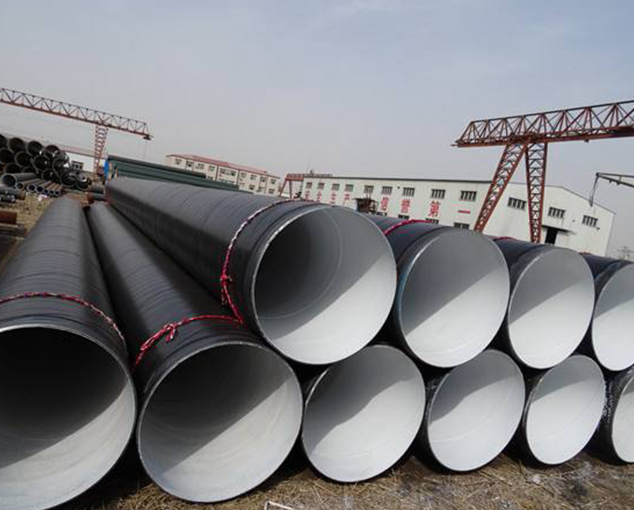

技术参数 产品规格:DN100-DN1800 钢管材质:Q235或...

组成部分 组份为环氧煤沥青底漆和面漆,都是以...

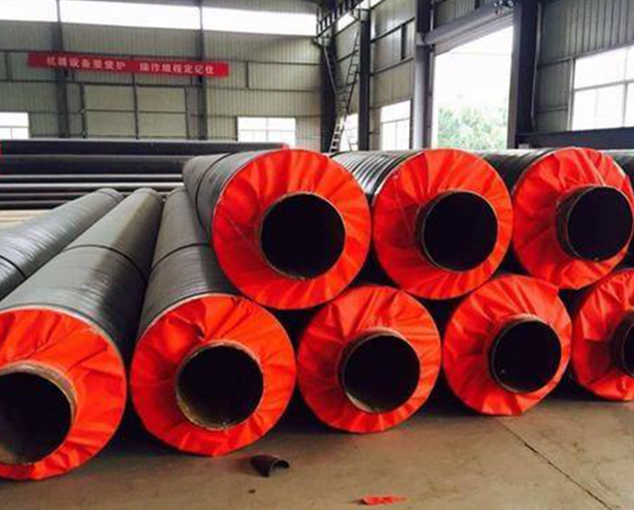

保温管特点 保温管道广泛用于液体、气体的输送...

保温管特点 保温管道广泛用于液体、气体的输送...

保温管特点 保温管道广泛用于液体、气体的输送...

外PE内EP久久亚91无码精品色午夜麻豆销售涂(滚)塑复合钢管无...

消防久久亚91无码精品色午夜麻豆,以钢管为基管,外壁涂装高附着...

矿用双抗久久亚91无码精品色午夜麻豆适用于-30℃120℃的工作环境,...

给排水久久亚91无码精品色午夜麻豆是专对于给排水而研发的一种新...

3PE麻豆AV免费在线观看钢管的材质分析 3PE麻豆AV免费在线观看钢管母材...

钢套钢蒸汽保温管是由外护钢管加钢管麻豆AV免费在线观看...

为客户提供更化、个性化的服务

保温钢管、麻豆AV免费在线观看钢管、久久亚91无码精品色午夜麻豆沧州国产麻豆激情无码视频色欲管道 管道生产商